2020-01-16

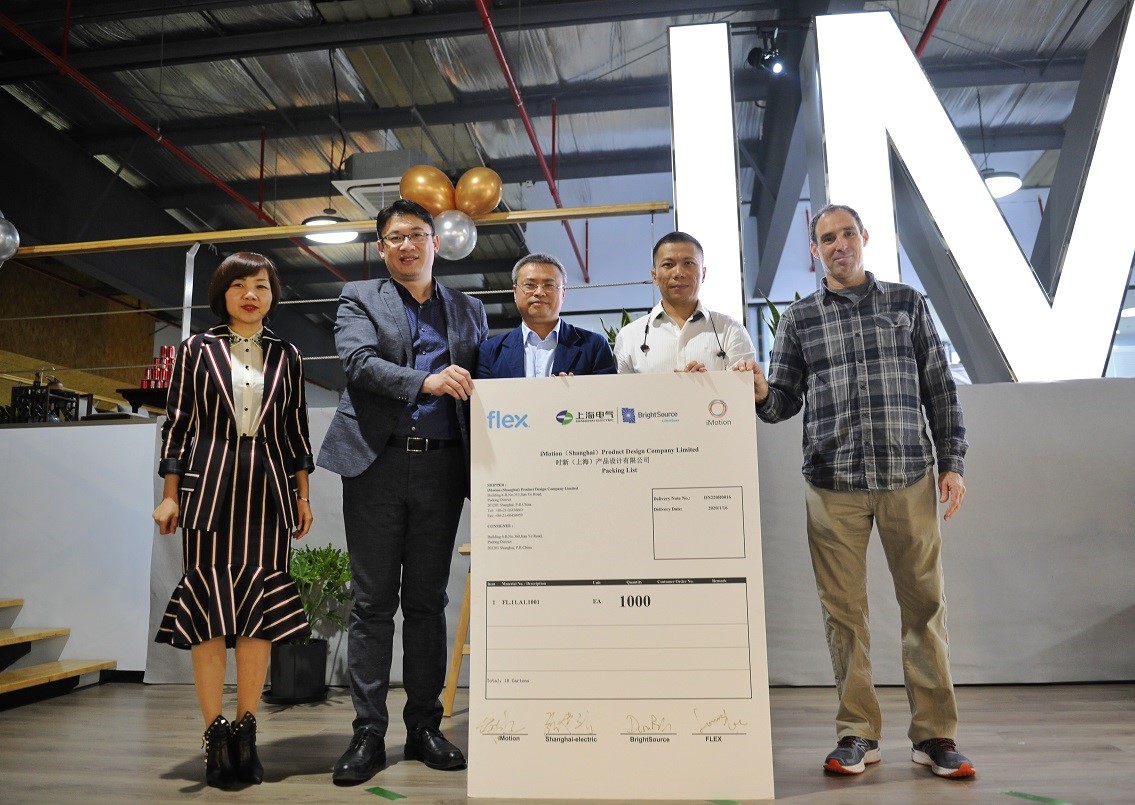

On January 16th, the Shipment Ceremony of " the third-generation BrightSource Solar Tracking System" was held at iMotion. Zhuo Li (iMotion CEO), Zhang Jianxin,( The Deputy General Manager of Shanghai Electric Bright Source Solar Energy Co., Ltd., ) and Danny Frank (Bright source Energy representative )attended the shipment ceremony.

At the ceremony, the last three of the 1,000 equipments were selected and given to the clients by the production representative, and then put them into the final shipping package to complete the product handover.

The Solar Tracking Module is the core component of the Solar Electric Generating System. It tracks the sun's rays, improves the accuracy, reduces the error of the reflection mirror, and maximizes the solar flow and generates the greatest energy for the concentrating tower.

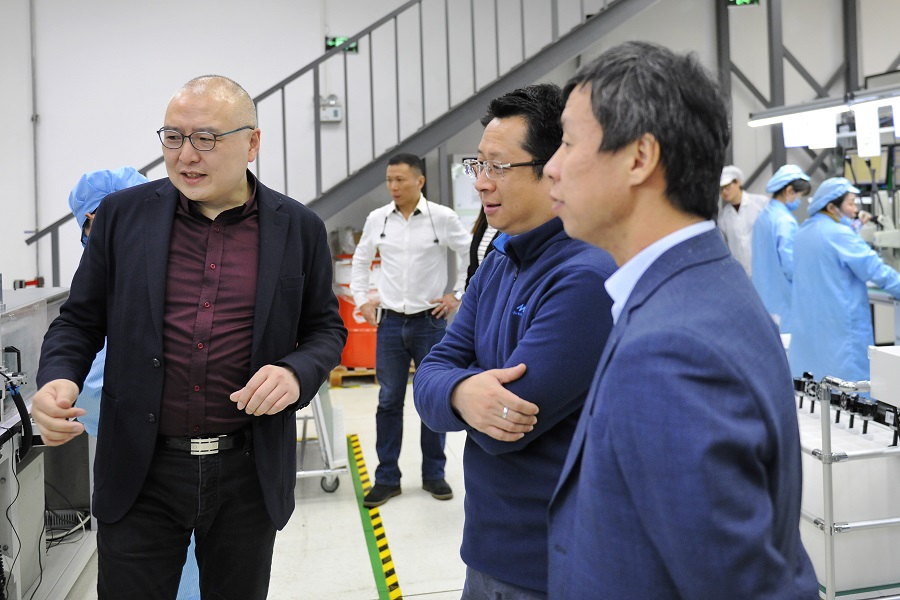

( Zhuoli introduced the products to visitors)

Founded in 2009, iMotion specializes in product development, design, production line establishment and mass production in various fields including consumption, medicine, industry and IoT. It is a seldom company in the global market that can achieve process from research and development to small-scale manufacturing business.

The first two generations of products have shipped more than 250,000 sets. Zhuoli believes that iMotion has strengthened its four major capabilities when making the first and second generation products: one is to precisely control solar energy flow; Second, we overcome the design difficulties of the wireless tower, so that the product can still maintain the same accuracy under the impact of strong wind; The third is to develop the support testing software to ensure that each component can reach the low energy consumption and high efficiency target; The fourth is to build a production line to complete product manufacturing and inspection.

(Gary introduced the products to visitors)

iMotion intervened in the design and verification phase of this project since May 2019, and shipped the 1,000th set today, which took only 8 months. Compared with the previous two generations, the third-generation products have higher requirements for technical evaluation and delivery period. The development team successfully completed the delivery task.

Zhuo Li said, “motor-driven worm and gear mode was applied to the third-generation products. We designed a whole set of product test equipment to simulate efficiency performance of the products in desert and windstorm, and made efforts to ensure that each product could pass the test. We introduced novel traceability system into the quality assurance system, so we could trace production date, raw materials, etc. for critical parts.”

(Zhuoli, iMotion CEO)

iMotion is committed to providing better and smarter solutions for every project. It is our responsibility to exceed industry standards and customer expectations. This delivery task also proves that iMotion is capable of providing leading solutions for our partners.

Mr. Zhang and Danny Frank also said that the cooperation was pleasant and affirmed the innovative spirit of the iMotion team during the research and development process.

(Gerhard Zebe )

(Gerhard Zebe )

(Zhang Jianxin)